Different Types of Conveyor Belts Used in Factories and Industries

Conveyor belts come in many shapes, sizes, and types, and each is suited for particular industries and needs. Hence it is essential to choose the right type of conveyor belt for your business, and any mistake such as choosing the wrong belt or improper installation can prove to be very expensive.

Here are some of the commonly preferred types of conveyor belts for mass production and distribution:

Plastic Conveyor Belts

These are belts made of lightweight but durable plastic and are preferred in industries with moist air, for these affect metal belts and may rust hem. They cannot be used for heavy loads because of their lightweight, so they are used in industries like pharmaceuticals, food production and manufacture of packaging products.

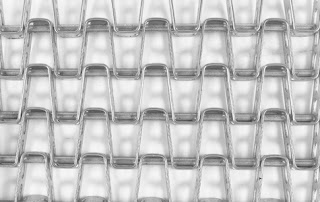

Flat Wire Belts

Flat wire belts are woven metal belts with a flat surface that are made of wire mesh. They can carry considerable loads, and the gap in the belts allow for air circulation, making them perfect for use in the food production industry. Flat wire belts are used in food manufacturing, baking factories, distribution facilities, and warehouses.

PVC Conveyor Belts

PVC stands for polyvinyl chloride, and it is a lightweight material that is often used as a substitute for plastic belt due to the former’s better resistance against oil and bacteria. This makes PVC the top choice for use in the mining industry to transport minerals from mines to the outside. They are corrosion resistant, hence can be used in areas with heavy moisture.

Magnetic Belts

Magnetic belts have moving magnets below the belt plates. These are used to transport magnetic minerals and metals properly, as the magnet below the belts keeps the materials on the belt in place. They are also often used in scrapyards and waste recycling facilities to separate important magnetic materials from the rest of the dump.

Comments

Post a Comment