How is Wire Mesh Made and Their Variants Produced by Wire Mesh Manufacturers

Wire mesh is a commonly used metal product that has diverse uses in the form of air filters, personal fencing, poultry fencing, construction of concrete slabs and so on. Wire mesh is generally made of steel or carbon, and come in a number of sizes based on the thickness of the wires and the size of the holes.

While wire mesh can be divided into many types based on the size of their holes and thickness of the wires, they can be divided into two categories based on the type of weave used in them. They are welded wire mesh and woven wire mesh, and their names are the indications of how the wires are joined together. Here is a brief outline of how wire mesh manufacturers build these wire mesh variants:

Welded Wire Mesh

It consists of steel wires welded together perpendicularly to form wire mesh.

First of all, metal wires, preferably stainless steel, are pushed through a series of machines with successively smaller diameters so that the wire passing through these dyes gets thinner and thinner until the desired thickness is achieved. All the final wires are collected by another machine and arranged in parallel inside an automatic welding machine. On top of the arrangement of the parallel wires, another layer of wires parallel to each other are dropped, but perpendicularly, so that both the top sets and bottom sets of wires are perpendicular to each other.

The machine is set up in such a way that it welds the exact spots in the arrangements where individual wires touch, in a uniform manner. Once this batch is done with, another batch comes in and the process is repeated.

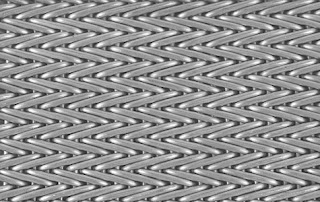

Woven Wire Mesh

It consists of steel or carbon wires woven together in an interweaving pattern to form the wire mesh.

The first step of diminishing the thickness of wires to desired levels uses the same method as in welded wire mesh, but that is where the similarity in manufacturing ends. In the case of woven wire mesh, loom equipment is used to form wires arranged in parallel to each other. The wires are laid out such that the space between each wire is uniform. Another set of wires in bough in simultaneously laid perpendicular to the former set of wires. A group of shuttles passes through alternate strands of wires, pulling in a wire perpendicular to the said strands. The wires are woven alternately in a uniform arrangement like how clothes are woven.

The shuttles can double back too, to create a yet another layer of weave for better strength if needed by the manufacturer. The patterns of weave can be varied based on the path taken by the shuttles when passing through the parallel wire arrangement.

Comments

Post a Comment